We recently came across an interesting white paper published by CENEX UK (April 2021, https://www.cenex.co.uk/app/uploads/2021/04/Refrigerated-Transport-White-Paper.pdf) who are a not-for-profit organisation specialising in low emission vehicle research and consultancy. The paper focuses on the environmental footprint and energy consumption of transport refrigerated units (TRU’s). CENEX explain the energy requirements of TRU’s and make recommendations for how they can be reduced.

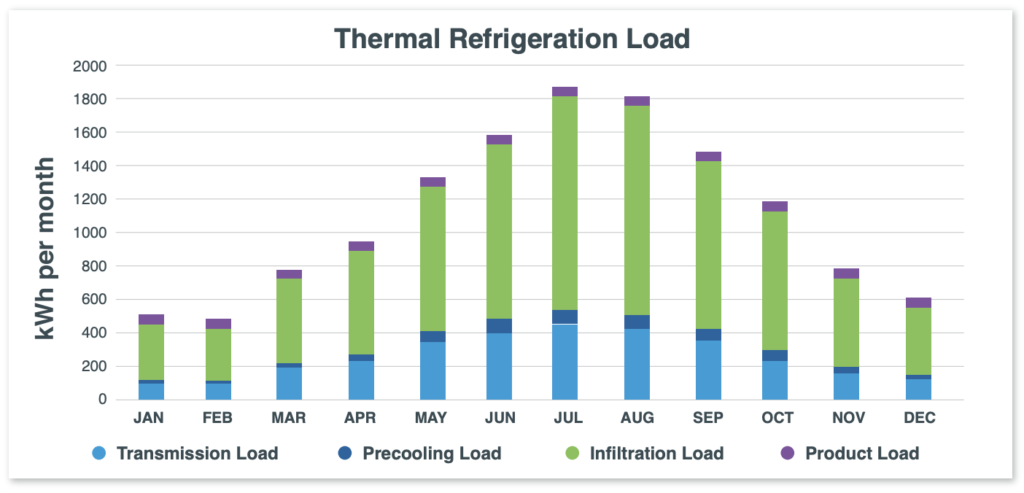

A particularly interesting graph is shown in the white paper :

In this graph the thermal refrigeration load is shown per month, based on a standard trailer (13.7 x 2.7 x 2.7m) operating 13 hours a day with 4 deliveries and transporting vegetables at 0°C.

CENEX specify the thermal refrigeration load (i.e. total cooling energy requirement) by separating the thermal load into transmission load, pre-cooling load, infiltration load and product load.

They write the following about infiltration load :

“Infiltration load is the thermal energy lost when the TRU doors are opened. This thermal energy is lost via three media:

a. the air: volume of chilled air that is replaced by outside ambient air

b. the product: thermal energy lost from the product to the now ambient internal air temperature

c. the refrigerator structures: additional thermal energy lost from the inside surface of the fridge walls, floor, ceiling and doors to the now ambient internal air”

We see in the graph that for all months the infiltration load (green areas) is approximately 70% of the total thermal load.

It is interesting to note that the infiltration load contributes to approximately three times more to the total thermal load than the transmission load. The transmission load is the measurement of heat transfer through the walls, ceiling and floor and takes place continuously, also during the period in which doors are closed (e.g during transit). It contributes to about 20-25% of the total thermal load.

In our previous blog “Will your refrigerated van lose you money without a climate barrier?” we concluded that during distribution routes, door openings are proven to drastically increase cooling energy use by 3 to 5.5 fold compared to when doors are closed during transit.

It is clear from CENEX’s research that the most obvious energy saving potential lies in reducing the infiltration load and we were pleased to read valuable research from an organisation aligned with our own objectives for energy saving initiatives for commercial transport.

BlueSeal air curtains have demonstrably reduced infiltration load by providing a barrier over rear and side doors to control this transfer of energy. For many years PVC strips have been used as a method to achieve this but have become outdated as the industry looks to more hygienic and secure solutions that are free from interference from drivers.

Creating effective climate barriers for temperature-controlled transport is at the heart of Brightec’s operation and for the past decade we have been proud to help companies manage infiltration load more effectively in a way that is does not inhibit the day-to-day operation of delivery drivers.

Further to this, BlueSeal air curtains has been proven in its ability to reduce approximately 30-45% of the infiltration load, resulting in a significant reduction of the total thermal load, which in turn reduces the carbon footprint and fuel costs of TRU’s.

The scale of infiltration loads

To elaborate on the tests performed by CENEX, we believe that 4 door openings a day offers a highly conservative estimate of what would occur a real-world scenario, especially during urban delivery distribution. It is not clear what the duration of door openings is in the tests, but we suspect that the infiltration load may be even greater than these findings suggest, and pose a genuine problem for transport operators.

While these findings demonstrate the scale of the problem when goods are transported at 0°C, the infiltration load is significantly greater during frozen transport where it is critical to manage effectively in order to maintain product integrity.

On pollution of auxiliary engines that provide power to the TRU’s

An interesting subject highlighted by the white paper is on the pollution caused by auxiliary cooling engines. Larger refrigerated transport vehicles (including semi-trailers and larger rigid trucks) often use an auxiliary engine, typically diesel, to power refrigeration units on the trailer. These cooling engines must compensate for the thermal load and keep the produce on a set temperature in the cargo space.

These auxiliary cooling engines emit a high level of pollution – 16 times more nitrogen oxides (NOx) and 40 times more particulate matter than the main engine of a truck. The impact of these vehicles footprint in terms of CO2 emissions is a real cause for concern which was one of our key motivations in finding a solution to manage this.