Temperature controlled products such as food and pharmaceuticals are distributed throughout cities and country sides by carriers who, for the most part, make use of a climate barrier at the doors to minimise the loss of cold when doors are opened. Traditionally this climate control has been managed by PVC strip curtains but we are seeing more and more companies adopting air curtains as their chosen method.

For vehicles that don’t make use of a climate barrier, cooling units require a significantly increased use of energy to ensure that these products are maintained at the prescribed temperature during distribution rides, i.e. rides with multiple stops / door openings.

The purpose of this study is to quantify this additional demand for cooling energy and estimate the extra use of diesel in a temperature-controlled vehicle without a climate barrier. As a courier, how important do you currently consider investing in effective climate control for your vehicles?

The test

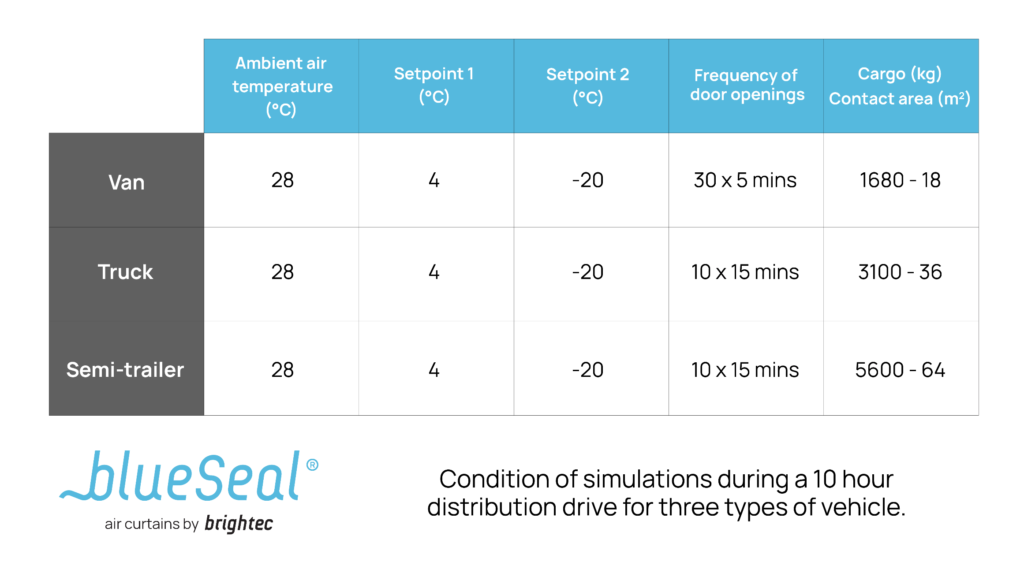

Using Brightec’s 2019 simulation model, daily energy use was calculated using inside air temperature set points of 4°C and -20°C and an outside (ambient) temperature of 28°C using three types of vehicles commonly used for distribution. Daily energy use is expressed in kWh or litre diesel. We’ve used typical coefficient of performance levels for transport refrigeration units (TRU) of 4.0 kWh/L(for set point 4°C) and 3.0 kWh/L(for set point -20°C), based on test results from Thermo King and Carrier.

For this simulation, we used the heat transfer coefficients of commonly used insulation panels and product packaging materials. For the three types of vehicle the table shows the cargo loads and their contact area with the inside air.

This simulation was performed under the condition that the cooling equipment has enough cooling capacity to maintain product temperature within a limit of 0.2°C. The following results are simulated on a 10 hour long distribution route, with allowances made for the frequency of door openings based on vehicle type (typically a van will be used for frequent, smaller deliveries whereas a larger vehicle may have less stops with longer time allowed for unloading larger payloads, see table).

Results

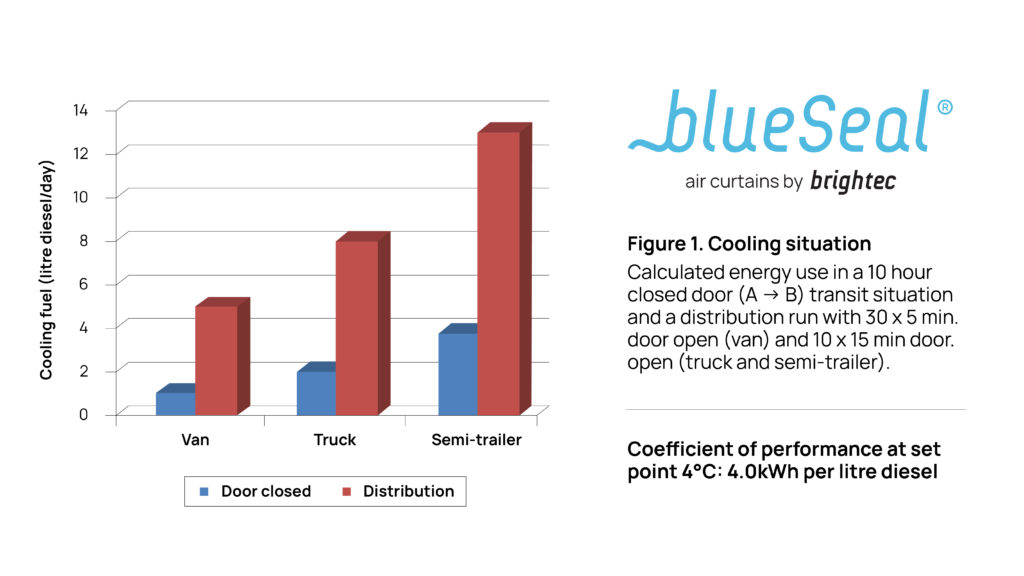

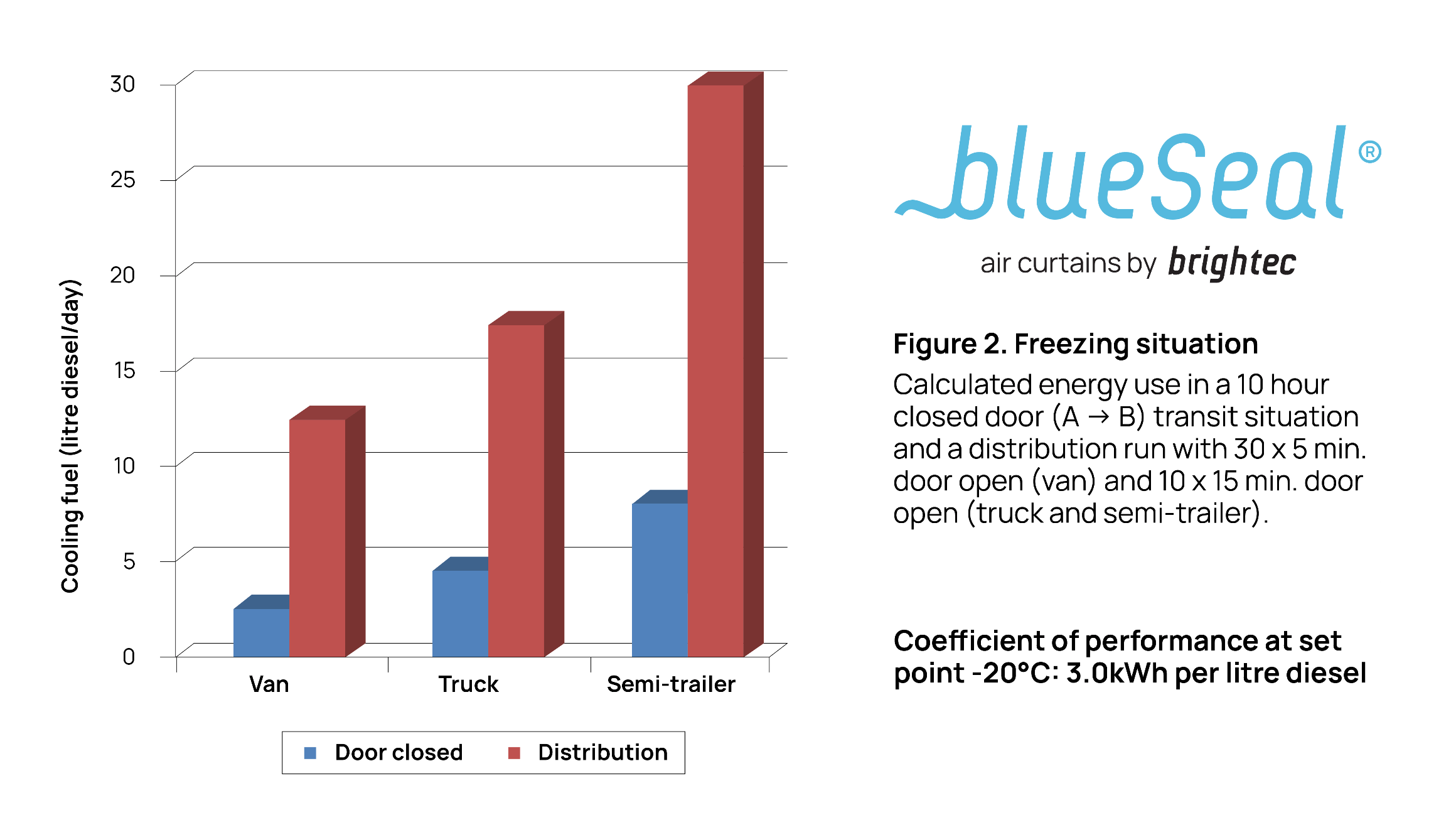

It should be noted that even during transit, products must still be subject to active cooling due to cold loss through walls, doors, floor and ceiling, although these demands are significantly lower than when exposed to outside air temperature. These demands are shown in figures 1 and 2 in blue bars for cooling (positive temperature) and freezing (negative temperature) scenarios.

For routes without door openings where goods are kept cool (at 4°C) this cooling demand is ca. 4, 8 and 14kWh for the van, truck and trailer respectively. This requires approximately 1, 2 and 3.5 litres of diesel – see figure 1. Frozen goods face a much higher energy demand of ca. 2.5, 4.5 and 8 litres of diesel a day – see figure 2.

During 10 hour distribution rides at cooling temperature without the use of a climate barrier during door openings, this demands a cooling energy use of 20, 32 and 50kWh/day requiring ca. 5, 8 and 12.5 litres of diesel a day for their respective vehicles. In a freezing scenario requiring a negative temperature, a cooling energy demand of 12.5, 17.5 and 30 litres of diesel a day is required to keep products at the required temperature.

Door openings during distribution rides increase the cooling demand by 3 to 5.5 fold requiring an additional 200-450% of cooling energy. In a typical semi-trailer, this equates to an additional cost of 9 litres of diesel a day to keep goods chilled. To keep goods frozen, this requires substantially more cooling fuel at an additional cost of 22.5 litres a day.

In order to roughly estimate the extra annual cooling costs due to door openings, we simulated with a yearly average ambient temperature of 16°C during 250 operational days.

For the cooling distribution routes, without use of a climate barrier, an extra 500 (vans), 750 (trucks) and 1,125 (semi-trailer) litres of diesel were required.

For the freezing distribution routes, without use of a climate barrier, these amounted to an additional 1,850 (vans), 2,380 (trucks) and 4,600 (semi-trailer) litres of diesel required to maintain products at the required temperature.

Note that we have focused solely on the increased energy usage and have not taken into account the extra costs that arise from the cooling machine that has to work harder and consequently requires more maintenance.

Conclusions

During distribution routes, door openings are proven to drastically increase the cooling energy use by 3 to 5.5 fold compared to when in transit. To keep goods cool at 4°C, door openings will increase diesel fuel use of up to 1,125 litres a year. For keeping these goods frozen at -20°C, up to 4,600 litres of diesel a year are required to account for door openings. While these fuel amounts are an approximation, they give a clear indication that a climate barrier will save substantial energy costs in distribution.

In future blogs we will further explore the cost saving potential of using BlueSeal air curtains as an effective method of climate control.